The electrification of the transportation sector has expanded beyond passenger cars to include heavy-duty vehicles, such as buses, trucks, and construction machinery. These vehicles play a crucial role in reducing greenhouse gas emissions and air pollution. However, their transition to electric power poses unique challenges, particularly in the development and deployment of traction batteries—the heart of heavy-duty electric vehicles (EVs).

Traction batteries in heavy-duty EVs face demanding requirements due to the vehicles’ higher weight, energy consumption, and operating conditions. This article explores the challenges associated with traction batteries for heavy-duty electric vehicles, alongside innovative solutions that are driving the industry forward.

The Role of Traction Batteries in Heavy-Duty EVs

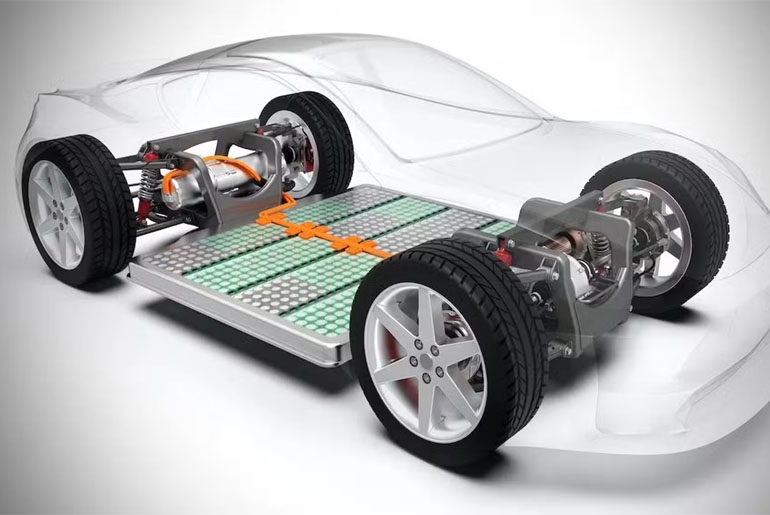

Traction batteries store and supply electrical energy to the motor, enabling the movement of electric vehicles. In heavy-duty EVs, these batteries must provide significantly higher energy capacity and power output than those used in passenger cars. This is because heavy-duty vehicles operate under harsher conditions, often carrying heavy loads, traveling long distances, or running continuously for extended periods.

Traction batteries are also integral to the charging process. Their design and capacity influence how quickly they can be recharged using EV charging infrastructure, a critical factor in minimizing vehicle downtime.

Challenges for Traction Batteries in Heavy-Duty EVs

-

High Energy Demand

Heavy-duty electric vehicles consume vast amounts of energy due to their size and weight. For example, an electric truck carrying several tons of cargo requires a much larger battery pack than a standard electric car. Meeting this energy demand without significantly increasing battery weight and size remains a major challenge.

-

Weight and Space Constraints

The weight of traction batteries directly affects the vehicle’s payload capacity. For heavy-duty EVs, minimizing battery weight while maximizing energy density is crucial to ensure efficiency and practicality. Additionally, space constraints in vehicles like trucks and buses make it difficult to accommodate large battery packs.

-

Thermal Management

Traction batteries in heavy-duty EVs generate significant heat during operation, especially under heavy loads or fast-charging conditions. Without proper thermal management, excessive heat can degrade battery performance, reduce lifespan, and pose safety risks.

-

Charging Infrastructure

The EV charging infrastructure required for heavy-duty electric vehicles is more demanding than that for passenger cars. High-capacity fast chargers are needed to minimize downtime, but such systems are costly to deploy and may strain local power grids.

-

Battery Lifespan and Degradation

Heavy-duty electric vehicles often operate continuously, putting their batteries through frequent charge and discharge cycles. This can accelerate battery degradation, reducing their lifespan and leading to higher replacement costs.

-

Sustainability and Recycling

The large-scale production and disposal of traction batteries raise environmental concerns. Ensuring sustainable sourcing of raw materials like lithium, cobalt, and nickel, and developing effective recycling methods, are critical challenges for the industry.

Innovative Solutions for Traction Batteries in Heavy-Duty EVs

-

Advanced Battery Chemistries

Innovations in battery chemistry are enhancing energy density and performance. For example:

- Lithium-ion batteries: Continual improvements in cathode and anode materials are increasing their energy capacity.

- Solid-state batteries: These promise higher energy density and safety by replacing liquid electrolytes with solid ones, making them ideal for heavy-duty electric vehicles.

-

Modular Battery Systems

Modular battery designs allow for scalability, enabling heavy-duty EVs to use multiple battery modules based on specific energy and power requirements. This approach optimizes space utilization and simplifies maintenance.

-

Advanced Thermal Management

Effective thermal management systems, including liquid cooling and phase-change materials, are essential for maintaining optimal battery temperatures. These systems ensure consistent performance and longevity, even in demanding operating conditions.

-

Fast-Charging Technologies

To address the downtime challenge, the development of high-power EV charging systems is crucial. Innovations such as ultra-fast chargers (capable of delivering 350 kW or more) and wireless charging systems are reducing charging times for heavy-duty electric vehicles.

-

Battery Swapping

Battery swapping offers a quick alternative to conventional EV charging. This involves replacing a depleted battery with a fully charged one at dedicated stations, minimizing downtime for heavy-duty EVs. While infrastructure-intensive, this solution is gaining traction in certain markets.

-

Energy Management Systems

Smart energy management systems optimize battery performance by predicting energy consumption patterns and balancing loads. These systems help extend battery life and improve energy efficiency, especially in fleet operations.

-

Integration with Renewable Energy

The integration of heavy-duty electric vehicles with renewable energy sources like solar and wind can reduce charging costs and enhance sustainability. For instance, on-site solar panels at EV charging depots can provide clean energy for charging, reducing dependency on fossil fuels.

-

Battery Recycling and Second Life

Recycling initiatives are addressing the sustainability challenge by recovering valuable materials from used batteries. Additionally, retired traction batteries from heavy-duty EVs can be repurposed for stationary energy storage, giving them a second life and reducing waste.

The Role of Charging Infrastructure

The success of heavy-duty electric vehicles depends heavily on robust EV charging infrastructure. The deployment of high-capacity charging stations along major freight corridors and urban areas is critical to supporting long-haul electric trucks and buses. Furthermore, integrating EV charging systems with smart grids and energy storage can enhance grid stability and efficiency.

Innovations like bi-directional charging (V2G) further highlight the synergy between heavy-duty electric vehicles and the energy ecosystem. V2G enables vehicles to return stored energy to the grid, supporting grid stability and renewable energy integration.

Future Outlook

Traction batteries in heavy-duty electric vehicles are evolving rapidly, driven by advancements in technology, infrastructure, and policy. The challenges of energy demand, weight, thermal management, and sustainability are being addressed through innovative solutions, paving the way for widespread adoption of heavy-duty EVs.

Governments, manufacturers, and energy providers must work together to accelerate the deployment of EV charging infrastructure and promote research into next-generation battery technologies. By tackling these challenges head-on, the industry can unlock the full potential of heavy-duty electric vehicles, contributing to a cleaner, more sustainable future.

Conclusion

Traction batteries are at the core of heavy-duty electric vehicles, enabling their transition to zero-emission transportation. While challenges such as high energy demand, battery degradation, and EV charging infrastructure persist, innovative solutions like advanced chemistries, fast-charging systems, and modular designs are addressing these issues.

As the adoption of heavy-duty electric vehicles grows, their integration with renewable energy and smart grids will further enhance their role in decarbonizing transportation. By continuing to invest in battery technology and EV charging infrastructure, the industry can drive the electrification of heavy-duty vehicles, ensuring a cleaner and more sustainable transportation future.