Electric vehicles (EVs) have emerged as a cornerstone of the global shift toward sustainable transportation. As EV adoption accelerates, significant emphasis is placed on the performance, safety, and longevity of their traction battery packs. Thermal management systems (TMS) play a crucial role in ensuring optimal battery performance, especially under varying operational conditions. Proper thermal regulation not only extends the lifespan of batteries but also enhances the charging and driving experiences. In this article, we delve into the intricacies of thermal management in EV traction battery packs and its implications for EV charging and efficiency.

The Role of Traction Battery Packs in EVs

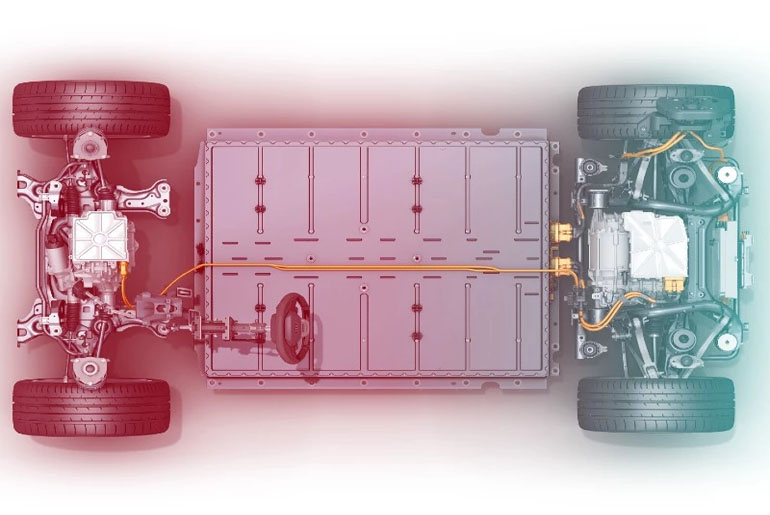

Traction battery packs are the heart of electric vehicles, supplying the energy required to power the electric motor. These packs consist of numerous lithium-ion cells organized into modules, and their efficiency directly impacts the range and performance of an EV. However, these batteries are sensitive to temperature fluctuations, making thermal management vital for their functionality.

Without effective thermal regulation, overheating or excessive cooling can lead to:

- Reduced battery capacity and range.

- Decreased charging efficiency during EV charging sessions.

- Accelerated degradation of battery cells.

- Safety hazards such as thermal runaway.

By maintaining the battery pack within an optimal temperature range (usually 20–40°C), EV manufacturers can enhance both safety and operational reliability.

Thermal Challenges in EV Battery Packs

Electric vehicles face unique thermal challenges arising from varying driving and charging conditions. These challenges can be grouped into three main scenarios:

- Heat Generation During EV Operation

During acceleration and regenerative braking, high currents flow through the battery pack, generating heat. In high-performance EVs, such as those designed for sports or heavy-duty applications, this heat can be substantial. - Thermal Strain During EV Charging

Fast charging is a key enabler of EV adoption, allowing drivers to recharge their vehicles quickly. However, rapid EV charging generates considerable heat within the battery cells. Without proper thermal management, this heat can reduce charging efficiency and increase battery wear. - Environmental Conditions

Electric vehicles are exposed to diverse climates. Cold temperatures can reduce battery efficiency and increase charging times, while extreme heat can cause overheating and safety risks.

Thermal Management Systems (TMS) in EVs

Modern EVs employ advanced thermal management systems to address these challenges. The design of a TMS typically involves active and passive cooling/heating methods:

- Liquid Cooling Systems

Liquid cooling is the most common solution in high-performance electric vehicles. A liquid coolant circulates through the battery pack, absorbing and dissipating heat. This system ensures uniform temperature distribution, making it ideal for fast EV charging scenarios. - Air Cooling Systems

Air cooling is a simpler and cost-effective solution, often used in smaller EVs. It relies on fans to circulate air around the battery cells. While less efficient than liquid cooling, it suits lower power and charging demands. - Phase Change Materials (PCMs)

Some EVs use PCMs, which absorb heat during phase transitions (e.g., solid to liquid). This method provides passive thermal regulation, maintaining temperature stability without active components. - Integrated Heating Systems

In colder climates, thermal management systems include heating mechanisms, such as resistive heating or heat pumps, to bring the battery pack up to its optimal operating temperature. This not only improves efficiency but also reduces EV charging time in low temperatures.

Thermal Management and EV Charging

Effective thermal management significantly enhances the EV charging experience by addressing:

- Fast Charging Efficiency

Advanced thermal systems prevent overheating during high-power EV charging sessions, allowing drivers to take full advantage of rapid chargers. - Battery Health

By keeping the battery temperature within a safe range, TMS reduces wear caused by frequent charging cycles. This extends the battery’s lifespan, ensuring that electric vehicles remain cost-effective and reliable over time. - Grid Interaction

Thermal management also impacts how EVs interact with the grid during Vehicle-to-Grid (V2G) operations. Efficient heat dissipation enables EVs to discharge stored energy without overheating, supporting grid stability and renewable energy integration.

Innovations in Thermal Management for EVs

With the rising demand for electric vehicles and the increasing prevalence of fast EV charging stations, manufacturers and researchers are exploring innovative thermal management solutions.

- Next-Generation Materials

Researchers are developing advanced coolants and heat-conductive materials to improve thermal efficiency. These materials enhance heat transfer rates while being lightweight and environmentally friendly. - Active Thermal Control Algorithms

Artificial intelligence and machine learning are being integrated into TMS to monitor and adjust battery temperatures in real-time. These algorithms optimize cooling and heating cycles, enhancing both performance and efficiency. - Integrated Battery and EV Charging Systems

Manufacturers are designing systems where thermal management is closely tied to EV charging protocols. By predicting heat generation during charging, these systems can preemptively activate cooling mechanisms, reducing stress on the battery. - Modular Battery Designs

Modular battery packs with individual thermal controls for each module are gaining traction. These designs allow for precise temperature regulation, enhancing safety and efficiency during both driving and EV charging.

Impact on EV Adoption

Thermal management is crucial for overcoming some of the key barriers to EV adoption, including range anxiety and charging times. As electric vehicles become more efficient and charging infrastructure continues to expand, thermal regulation systems ensure:

- Improved Battery Lifespan: Effective thermal management reduces the risk of premature battery degradation, enhancing the total cost of ownership for EV users.

- Reliable Performance Across Climates: Whether in hot deserts or freezing winters, advanced TMS ensures consistent EV performance.

- Faster EV Charging: By preventing overheating, TMS supports the development of ultra-fast EV charging stations, making electric vehicles more convenient for long-distance travel.

The Future of Thermal Management in EVs

As the EV market evolves, so will the demands placed on thermal management systems. The rise of high-performance EVs, solid-state batteries, and V2G technologies will require even more sophisticated TMS designs. Moreover, with governments worldwide pushing for zero-emission transportation, effective thermal management will play a key role in ensuring the sustainability and reliability of EVs.

Conclusion

Thermal management is at the core of electric vehicle design, influencing everything from driving range to the efficiency of EV charging systems. By addressing thermal challenges and integrating innovative technologies, automakers are enhancing the safety, performance, and appeal of EVs. As the world shifts toward electrified transportation, robust thermal management systems will be instrumental in powering the future of sustainable mobility.