Powering the Future of EV with Silicon Carbide (SiC)

In the rapidly evolving landscape of electric vehicles (EVs), enhancing efficiency and performance is crucial. Silicon Carbide (SiC) has emerged as a transformative material that significantly boosts the efficiency and effectiveness of EV power systems. Unlike traditional silicon, SiC offers superior properties such as higher thermal conductivity, greater energy efficiency, and the ability to handle higher voltages and temperatures.

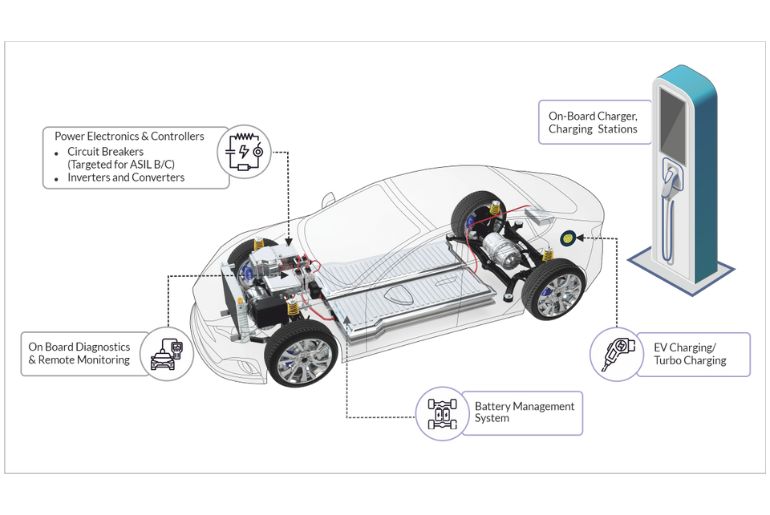

These attributes make SiC an ideal choice for key EV components, including power inverters, onboard chargers, and battery management systems. By reducing energy losses and improving heat management, SiC technology not only extends the range and lifespan of EVs but also accelerates charging times, addressing critical challenges in the EV industry. This introduction sets the stage for a deeper exploration of how SiC is revolutionizing the electric vehicle market and driving the future of sustainable transportation.

Superior EV Power Electronics with SiC

1. Enhanced Efficiency:

Silicon Carbide (SiC) offers significantly higher electron mobility and lower ON resistance compared to traditional silicon, leading to reduced conduction and switching losses. This efficiency translates into better power conversion performance, which is critical for high-demand applications like electric vehicles (EVs).

2. Thermal Management:

SiC’s excellent thermal conductivity allows devices to manage heat more effectively, enabling them to operate at higher temperatures without performance degradation. This property reduces the need for extensive cooling systems, allowing for more compact and lightweight electronic designs.

3. High Voltage and High-Frequency Operation:

SiC semiconductors can endure higher electric fields, making them suitable for high-voltage applications. Additionally, their ability to switch at higher frequencies without significant losses enhances the performance of power electronics, such as inverters and DC-DC converters, making them more efficient and responsive.

4. Durability and Reliability:

The robust nature of SiC devices means they can withstand higher thermal and electrical stresses. This durability leads to a longer operational lifespan and greater reliability, reducing the frequency and cost of maintenance in industrial and automotive applications.

5. EV Size and Weight Reduction:

The intrinsic properties of SiC allow for the design of smaller, lighter power electronics by enabling higher power densities. This contributes to the overall reduction in weight of EVs, which in turn improves their range and efficiency.

6. Faster Charging Times:

SiC’s ability to handle higher power levels efficiently supports the development of faster chargers for EVs. This capability reduces charging times significantly, which is a critical factor for the widespread adoption of electric vehicles.

Enhancing Battery EV Performance and Lifespan

1. Efficient Power Conversion:

SiC-based power electronics enable more efficient DC-DC converters and inverters, reducing energy losses during power conversion. This efficiency translates into less wasted energy, ensuring that more power from the battery is used effectively, thereby improving the overall performance of the EV.

2. Reduced Thermal Stress:

The superior thermal management capabilities of SiC devices minimize heat generation during operation. This reduction in thermal stress helps maintain optimal battery temperatures, preventing overheating and thermal runaway, which are critical factors in prolonging battery life.

3. Increased Charge-Discharge Cycles:

With lower energy losses and better thermal control, SiC components contribute to a more stable and consistent charge-discharge cycle. This stability reduces the wear and tear on the battery cells, extending their operational lifespan and reliability.

4. Higher EV Power Density:

SiC technology allows for the design of more compact and lightweight power electronics, which can handle higher power levels without increasing the size or weight of the battery pack. This higher power density enables more energy storage in a smaller footprint, enhancing the overall battery capacity and efficiency.

5. Fast Charging Capabilities:

The ability of SiC devices to operate at higher frequencies and voltages supports faster charging technologies. This capability not only reduces the charging time for EV batteries but also ensures that the rapid charging process does not adversely affect the battery’s health and longevity.

6. Enhanced Energy Recovery:

SiC-based systems can improve the efficiency of regenerative braking systems by converting more of the kinetic energy back into stored electrical energy. This enhanced energy recovery reduces the strain on the battery during acceleration, contributing to a longer battery lifespan.

7. Consistent EV Performance Under Stress:

SiC’s robustness ensures consistent performance under various operating conditions, including extreme temperatures and high power demands. This reliability ensures that the battery can deliver peak performance without degradation, even in challenging environments.

Overcoming Thermal EV Management Challenges

1. Superior Thermal Conductivity:

SiC (Silicon Carbide) has a significantly higher thermal conductivity compared to traditional silicon, allowing it to dissipate heat more efficiently. This characteristic helps in maintaining lower operating temperatures for power electronics, even under high power loads.

2. Enhanced EV Heat Dissipation:

The ability of SiC devices to operate at higher junction temperatures without performance degradation ensures that heat generated during operation is managed more effectively. This enhanced heat dissipation is crucial for preventing hotspots and ensuring uniform temperature distribution across the device.

3. Compact and Lightweight Designs:

The high thermal efficiency of SiC components enables the design of more compact and lightweight cooling systems. This reduction in size and weight is particularly beneficial for EVs, where space and weight savings directly impact vehicle performance and range.

4. Improved Reliability and Longevity:

By effectively managing thermal loads, SiC-based systems reduce thermal stress on electronic components. This reduction in stress translates into higher reliability and longer operational life for both the power electronics and the battery systems.

5. Optimized Cooling Solutions:

The implementation of advanced cooling solutions, such as liquid cooling and integrated heat sinks, is facilitated by the high thermal performance of SiC devices. These optimized cooling solutions ensure that even under peak operating conditions, the thermal management system can maintain safe temperature levels.

6. High-Temperature Operation:

SiC devices can operate efficiently at higher temperatures compared to silicon-based counterparts. This high-temperature capability reduces the need for extensive cooling systems, simplifying the thermal management strategy and reducing overall system complexity.

7. Cost-Effective Thermal Management:

The efficiency of SiC technology in handling thermal loads reduces the need for expensive and bulky cooling infrastructure. This cost-effectiveness makes SiC an attractive choice for automotive manufacturers looking to enhance thermal management without significantly increasing costs.

8. Thermal Simulation and Modeling:

Advanced thermal simulation and modelling techniques are used to design SiC-based systems. These tools help engineers predict thermal behaviour accurately and optimize the thermal management system to ensure peak performance and reliability.

By leveraging these superior thermal management capabilities, SiC technology not only enhances the performance and efficiency of EV power electronics but also contributes to the overall reliability and longevity of the vehicle’s powertrain system.

SiC’s Transformative Impact on the EV Industry

Silicon Carbide (SiC) is revolutionizing the electric vehicle industry by significantly enhancing the efficiency, performance, and reliability of EVs. As a superior alternative to traditional silicon, SiC’s exceptional thermal conductivity, high voltage tolerance, and minimal energy losses have made it integral to advancing EV technology. The adoption of SiC in power inverters, onboard chargers, and battery management systems has led to improved range, faster charging times, and greater overall vehicle efficiency.

These advancements not only address key challenges in the EV market but also pave the way for a more sustainable and widespread adoption of electric vehicles. The transformative impact of SiC underscores its critical role in driving the future of the automotive industry, highlighting its potential to support the transition to cleaner, more efficient transportation solutions.