Maximizing Efficiency and Stability: The Power of Tubular Stabilizer Bars in Electric Vehicle Suspensions

Maximizing Efficiency and Stability: The Power of Tubular Stabilizer Bars in Electric Vehicle Suspensions

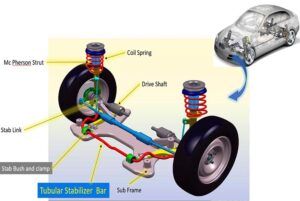

Tubular (Hollow Bars) stabilizer bars, also known as anti-roll bars or sway bars, play a crucial role in the suspension system of vehicles, including those in the e-mobility space. These bars play a crucial role in enhancing the overall stability and handling characteristics of a vehicle, including EVs. Tubular anti roll bars can be up to 45% light in weight as compared to solid bars for same or better performance.

In the context of e-mobility, where electric vehicles (EVs) are becoming increasingly popular, the use of tubular stabilizer bars has gained significance due to the unique characteristics of EVs. Electric vehicles tend to have a higher center of gravity due to the placement of heavy battery packs, which can result in increased body roll during turns.

Unlocking Efficiency – How Tubular Stabilizer Bars Enhance Electric Vehicle Performance

Here are a few ways in which tubular stabilizer bars contribute to EV efficiency:

Here are a few ways in which tubular stabilizer bars contribute to EV efficiency:

- Improved Handling and Stability: Tubular stabilizer bars help minimize body roll during cornering by transferring the lateral force between the wheels. This enhances the vehicle’s stability and improves handling, allowing drivers to maintain better control. With improved stability, EVs can navigate corners more efficiently, reducing the need for sudden braking or acceleration, and thereby optimizing energy usage.

- Enhanced Traction and Efficiency: By reducing body roll and maintaining better tire contact with the road, tubular stabilizer bars help improve traction. With increased traction, EVs can effectively utilize the available power from their electric motors, especially during acceleration. This translates to improved efficiency as the EV can accelerate more smoothly and efficiently, minimizing energy losses.

- Regenerative Braking Optimization: Many electric vehicles utilize regenerative braking systems that capture energy during braking and convert it into electrical energy to recharge the battery. Tubular stabilizer bars aid in maintaining a balanced weight distribution during braking, reducing weight transfer to the front wheels and improving overall braking performance. This can maximize the effectiveness of regenerative braking, allowing for greater energy recovery and thus improving EV efficiency.

- Weight Reduction: Tubular stabilizer bars are typically lighter than their solid counterparts, reducing the overall weight of the vehicle. As EVs aim for increased efficiency and extended range, minimizing weight becomes crucial. By using lighter stabilizer bars, EV manufacturers can offset the weight of other components, such as batteries, and improve the overall efficiency and range of the vehicle.

- Aerodynamic Considerations: Tubular stabilizer bars, being more streamlined compared to solid bars, offer improved aerodynamic properties. By reducing drag and minimizing turbulence around the underbody, EVs equipped with tubular stabilizer bars can experience reduced energy losses due to air resistance. This aerodynamic advantage can contribute to improved efficiency, particularly during high-speed driving conditions.

- It’s important to note that the overall impact of tubular stabilizer bars on EV efficiency will vary depending on various factors, such as the vehicle’s design, weight distribution, suspension setup, and driving conditions. Nevertheless, when properly engineered and integrated, tubular stabilizer bars can contribute to a more efficient and optimized electric vehicle.

- In the e-mobility space, where efficiency is a key consideration, the use of tubular stabilizer bars can contribute to improving the overall driving experience and safety of electric vehicles. By minimizing body roll and maintaining better control over the vehicle’s dynamics, these stabilizer bars help optimize energy consumption and ensure a smoother ride for EV drivers and passengers

Sogefi ADM: Providing Suspension Solutions for E-Mobility OEMs in Various Vehicle Segments

Sogefi ADM is a leading provider of suspension solutions for E-Mobility original equipment manufacturers (OEMs) across multiple vehicle segments. The company offers its expertise to prominent OEMs such as JBM E-Buses, Eka Mobility’s Light Commercial Vehicles, Switch Mobility’s Commercial Vehicles, Tata Motors’ Passenger Vehicles, and many more. With a focus on E-Mobility, Sogefi ADM delivers high-quality suspension products tailored to the specific needs of electric vehicles in the market.

Sogefi ADM is a leading provider of suspension solutions for E-Mobility original equipment manufacturers (OEMs) across multiple vehicle segments. The company offers its expertise to prominent OEMs such as JBM E-Buses, Eka Mobility’s Light Commercial Vehicles, Switch Mobility’s Commercial Vehicles, Tata Motors’ Passenger Vehicles, and many more. With a focus on E-Mobility, Sogefi ADM delivers high-quality suspension products tailored to the specific needs of electric vehicles in the market.

About Sogefi ADM Suspensions

Sogefi ADM is a JV Equity participation of 74% by Sogefi Group & 26% by ADM Group. We offer a complete solution for elastic suspension components for passenger cars, light commercial and heavy-duty vehicles. The plant has the capability to design, prototype, validate and manufacture Stabilizer Bars and Torsion Bars. https://www.sogefigroup.com/en/sogefi-group/joint-ventures/main.html

About Sogefi Group

Sogefi Group is a leading global supplier of original parts for the automotive industry, with 40 years’ experience. Sogefi designs, develops and produces filtration systems and flexible suspension components as well as airb management and engine cooling systems. Sogefi S.p.A. is listed on the Milan Stock Exchange in the STAR segment and is a partner to the world’s leading manufacturers of cars, commercial vehicles and earth-moving equipment. Today, it has a presence in 18 countries on 4 continents, with 37 manufacturing sites.

About ADM Group

With more than Two Decades of experience in disrupting the Global Automotive Industry, the ADM group has been Leading the creation of Smart, Sustainable Solutions for more than Two Decades. What began in 1998 with Tube Solutions for OEM and Tier II Automobile Players, now extends Offerings across Emission, Fluid Transmission, Flexible Metal, Precision Tubes Elastic suspension and Future Mobility Products. The ADM group’s key focus lies in Delivering Excellence across Engineering Supply Chain and Industry leasing solutions for automotive & industrial needs.

For more information email us @ deepak.tyagi@adm.sogefigroup.com