-By Pat Kowalyk, Field Application Engineer, Vicor

Look under the hood of an electric vehicle and you may be surprised to find a conventional 12V lead-acid battery or an additional 48V battery. You may wonder why does an EV need a conventional battery when there’s a 400V or 800V battery already in the vehicle to power the motors? Today the 12V or 48V batteries power all the other systems in the vehicle, but they add cost and weight and take up valuable space. Why not remove the 12V battery and use the 400 – 800V battery to power everything in the car?

The simple answer is that many automotive systems, especially safety systems, must respond quickly to sudden changes in power, and batteries historically have much better response times than DC-DC power converters.

Until recently, power systems engineers have not had options for safely and reliably converting 800V or 400V down to 48V or even 12V with a fast transient response and without adding unwanted volume or weight.

Additionally, new EV’s consume up to 20x more power (going from 3kW to over 50kW) than combustion engines which puts significant strain on the power delivery network, when using hard switching DCDC converter topologies, resulting in a hefty increase in conventional power electronics that consume space, increase weight and limit range.

Because of EV power requirements, it is time to take a fresh look at how to best deliver the power needed rather than trying to retrofit the internal combustion engine (ICE) power delivery architecture.

Using traditional DC-DC power converters EVs cannot handle the associated ~20x increase in power without making performance and functionality compromises which diminish their appeal. This fresh look is not a light remodeling exercise. It is a knock-down and rebuild project that needs to be explored through the lens of innovation, not convention.

The conventional progress achieved toward electrification has been driven by adding more and higher-powered batteries to cars. These batteries are heavy and large. The latest models are touting 800V batteries, but the same vehicle is also hauling a 12V and maybe even a 48V battery. With package space and weight at a premium, three batteries is inefficient and unnecessary.

Where conventional approaches add batteries, a fresh, innovative approach removes a battery, frees package space and reduces weight, all while increasing much need power transient response.

The end of the road for 12V batteries?

High-performance power conversion is essential to removing a battery. More specifically, faster transient response from a converter is the most important variable. If a high-performance power converter can deliver the rapid response equal to or better than a 12V battery (250A/ms), then removing the 12V battery and its associated weight and packing space becomes plausible.

The most essential role of the 12V battery has been to provide a reservoir of power for loads that require a lot of power. The typical load in a vehicle will have two types of current draw—one for start-and one for steady-state operation. When power is initially applied to a particular load, either raw power is applied or the power is already present and only an enable signal is needed.

The loads that use raw power will draw a large amount of current either to charge a capacitor or to turn an armature. Then, after the load is energized (start-up), the current drops down and the load operates continuously (steady state). This initial current draw is what makes the battery a good option for a legacy ICE vehicle, but not for an EV where weight dramatically impacts range and performance. So it makes sense to eliminate the heavy lead-acid or lithium 12V battery and replace it with a lighter, compact and high-performance DC-DC converter that delivers very fast transient response.

12V battery vs. high-performance power modules

Replacing the 12V battery in a vehicle with a traditional converter may cause the load voltage to drop low enough that the load turns off, thus causing a reboot in a vehicle. A key parameter to look at is the load voltage deviation during a change in current relative to time. This is referred to as the transient response; the lower the voltage deviation, the higher the performance of the system.

When designing a new electric vehicle, one needs to consider a great number of new high-tech solutions. A modular power approach combined with topologies like the proprietary Vicor Sine Amplitude Converter (SAC™) allows one to far exceed the slew rate—the transient response—of a 12V lead-acid battery.

A modular approach leveraging SAC can process thousands of amperes from the high voltage battery to the load eliminating any dips or loads falling out of regulation. Bench testing shows that modular power can deliver a response three times faster than a typical 12V battery (Figure 1) .

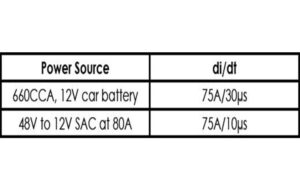

Automobile manufacturers typically require 250A/ms for their fastest loads, which 12V batteries can achieve (75A/30μs). The Vicor modular approach can provide faster transient response (75A/10μs), creating a “virtual battery” that responds three times faster than 12V.

Replacing 12V battery with a faster, lighter and smaller high performance power converter

Replacing 12V battery with a faster, lighter and smaller high performance power converter

Modular power combined with SAC is part of what makes this solution optimal for automotive power. The SAC has a turns ratio, called the K-factor that is a ratio of the primary to secondary turns. A key advantage of this topology is that any primary-side capacitance is multiplied by the K-factor squared. For a 12V-to-48V conversion, the K-factor is ¼, which means the effective secondary capacitance is four squared, or 16 times the primary capacitance.

The Vicor NBM is an ideal converter to transfer the energy load from a mechanical source, which is on all the time, to an electrical source of energy that cycles on and off, allowing better control and better efficiency.

The NBM in conjunction with the SAC allows an engineer to create a virtual battery that replicates the essential properties of a physical battery, complete with all the benefits of a battery but without the weight, size or temperature limitations of a battery. (Figure 2)

Using a modular approach allows the designer to split the power source into different zones. Instead of having one centralized power architecture, the designer can place an NBM in the dashboard, in the trunk and or by all four wheels.

Having the power source closer to the load reduces parasitic inductances and series resistances for a high-performing power system. The same approach also applies to HV-to-48V conversion which would show similar performance, creating a 48V virtual battery.(Figure 3)

It makes sense to use the traction motor battery which is the largest energy source in the vehicle to down-convert to different safe voltages. Typically, the traction motor battery in an electric vehicle is either 400V or 800V and will be quickly replaced with 1,200VDC or 1,400VDC.

A modular approach eliminates any internal series inductance on the input or output and can process easily 700,000 amperes per second or 700 amperes per millisecond. It can be easily be paralleled in an array to create a large power-processing system and has isolation from any primary bus voltages which are 60V or higher.

The NBM in theory is only thermally limited in terms of its power capability and if properly cooled it can process very high amount of power. It provides the added benefit of the bidirectional operation and can start up in either direction.

Revolutionize your electrification with modular power

In this new age of electrification, OEMs will benefit from taking a fresh look at how cars are electrified. By designing the power delivery network from the ground up and considering all of the vehicles’ electrical needs,

you can derive far more benefits and deliver far greater performance. In short, by switching to modular power you can eliminate the 12V battery and achieve enhanced transient response, decreased weight and additional package space– all of which contribute to extended range and better overall performance.

(Source- www.bisinfotech.com)