Freudenberg Sealing Technologies has announced that it has achieved production of one million units. Gaskets from this plant are installed by e-vehicle manufacturers throughout Europe.

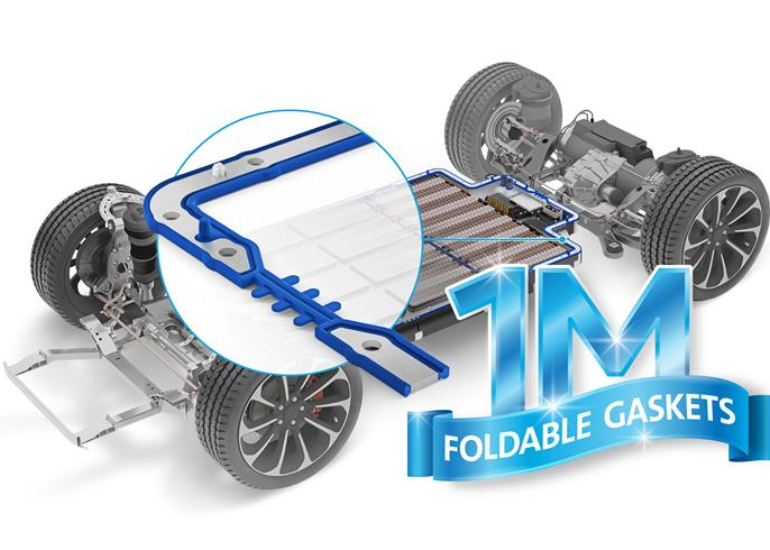

The number of electric vehicles on the road is steadily increasing; by 2030, more than 100 million electrically powered vehicles are estimated to be on the road worldwide. To ensure that drivers may use their EVs for as long as feasible, a well-protected battery system is required. In regular operation, for example, splash water must be kept out of the gap between the battery cover and the housing. The battery housing gasket, which can be up to eight meters long depending on the size of the enclosure, handles this task. The seal, however, must do much more than just guard against infection. If there is a heat incident in the battery, it should also aid to keep the flames contained.

Marc Nicolas, Director Gaskets at Freudenberg Sealing Technologies in Langres, said, “This huge number is a great success and an outstanding achievement by the entire local team. It was also a huge challenge, as the plant in Langres had to be completely redesigned to produce the foldable gaskets and the processes had to be adapted accordingly. All this

proceeded smoothly during continuous operations. In addition, the order quantities, timings and the design of the foldable gaskets changed several times during the ongoing production process. The fact that we were able to deliver impeccable quality despite all this is thanks to a well-functioning, highly motivated team.”

Freudenberg Sealing Technologies has created a solution that exceeds client expectations by producing the foldable gasket.

Strength is provided by a segmented aluminum carrier with numerous sealing profiles on the outer edge, which also incorporates plastic retention fittings. These are used to swiftly and efficiently attach the gasket to the battery housing cover. The carrier segments are linked together by a highly flexible continuous sealing profile. This allows it to account for minor manufacturing tolerances in the housing.

Frederic Boyer, Head of Marketing Gaskets at Freudenberg Sealing Technologies, said, “With the foldable gasket technology and the ability of Freudenberg Sealing Technologies to scale the production quickly and robustly, we are showing that this innovative solution plays a key role in ensuring safety and reliability in the fast-growing electromobility market. It’s important that every gasket is developed in close cooperation with our customers. This is the only way for us to meet changing expectations with optimal solutions and be a reliable partner for the industry in the field of modern mobility applications.”