Deemed to be the new face of next-generation vehicles that are centered around smart mobility solutions with cleaner fuel alternatives, Electric vehicles (EVs) are integrating into the automobile sector at a feverish pace.

Deemed to be the new face of next-generation vehicles that are centered around smart mobility solutions with cleaner fuel alternatives, Electric vehicles (EVs) are integrating into the automobile sector at a feverish pace.

Spurred under the pressure of a post-pandemic world that played an instrumental role in changing the entire landscape of the automobile industry in India, consumers are becoming more inclined towards adopting electric vehicles as the next best thing to counter the rising rate of carbon emissions and fuel costs.

Instigated under the tremendous push of major government bodies, Electric Vehicles are slowly becoming the more sustainable transportation option for Indians who are showing interest in investing in this new model of greener mobility.

Following the predictions of some industry experts, car shoppers around the world will have the choice of more than 400 EV models that could push EV sales to between 6 million and 11 million units by 2025.

Despite the several attempts of innovators pioneering in this fledgling industry in the last few years, certain EV Design Challenges are hard to overcome that have stunted the growth and sales of EVs to some extent.

When we talk about EV Design Challenges in 2023, it involves several technical and engineering issues that must be overcome to make EVs more practical and widely adopted.

Moving forward to surpass the present EV Design Challenges in 2023 in the industry, firstly we have to identify the issues that plague the growth of this mobility option.

Top 6 Electric Vehicle (EV) Design Challenges in 2023

To make certain pure-electric and hybrid-electric vehicles safe, reliable and perform efficiently, major EV Design Challenges in 2023 designers are expected to overcome includes,

EV Design Challenges in 2023 #1: Work in Progress for Charging Infrastructure

In efforts to realize the full potential of these sustainable options, Electric Vehicles must come on par with the performance, efficiency and reliability of traditional ICE-based engines. To achieve this feat, the biggest obstacle is long-distance travel where frequent charging stations are not always available along the route. Installing more charging stations with a faster time period requires massive investment and support to create a more robust charging infrastructure in the near future.

In efforts to realize the full potential of these sustainable options, Electric Vehicles must come on par with the performance, efficiency and reliability of traditional ICE-based engines. To achieve this feat, the biggest obstacle is long-distance travel where frequent charging stations are not always available along the route. Installing more charging stations with a faster time period requires massive investment and support to create a more robust charging infrastructure in the near future.

EV Design Challenges in 2023 #2: Less Efficient Batteries

Currently, a regular lithium-ion battery for vehicle electrification provides its drivers a range of 400 to 500 km on average. Considering the normal travel routine of a consumer, this is considered a limited driving range since drivers expect a range of more than 644 km. A major reason for this includes inefficient battery design that is limited by the power density related to the mass and size of the pack. Increasing the mass can negatively affect the vehicle’s braking, handling and acceleration, and will require more energy.

Currently, a regular lithium-ion battery for vehicle electrification provides its drivers a range of 400 to 500 km on average. Considering the normal travel routine of a consumer, this is considered a limited driving range since drivers expect a range of more than 644 km. A major reason for this includes inefficient battery design that is limited by the power density related to the mass and size of the pack. Increasing the mass can negatively affect the vehicle’s braking, handling and acceleration, and will require more energy.

EV Design Challenges in 2023 #3: Matching up to Traditional Vehicle Range & Performance

Another major EV Design Challenges in 2023 for vehicle electrification is the limited driving range of lithium-ion batteries. Apart from this, battery’s design is also limited by the size and mass of the pack since increased mass will need more energy for vehicle movement and can then negatively affects the vehicle’s handling, acceleration as well as braking. Beyond providing a limited driving range, all-electric vehicle batteries become less efficient over time.

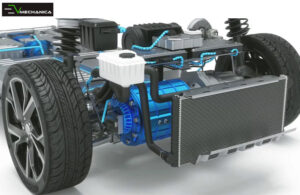

EV Design Challenges in 2023 #4: Weight and Aerodynamics

Considering the heavy weight of the batteries and electric drivetrain in EVs, EVs become less aerodynamic and more difficult to design, which can indirectly impact vehicle performance and range.

Considering the heavy weight of the batteries and electric drivetrain in EVs, EVs become less aerodynamic and more difficult to design, which can indirectly impact vehicle performance and range.

EV Design Challenges in 2023 #5: Fluctuating Automotive Supply Chain

Being a new force in the industry, the EV supply chain shows frequent fluctuations as OEM-supplier relationship varies drastically from gas-powered vehicles to EVs. According to the industry experts, there are roughly 3,800 fewer parts in an electric motor as compared to a traditional internal combustion engine. This offers various advantages for the manufacturer and expecting car owner, that includes significant cost reduction (and economies of scale because there are fewer suppliers), less maintenance, and have an overall reduced cost of ownership.

EV Design Challenges in 2023 #6: EV Reliability is Key

Generally, power components like motors, batteries and power electronics are more vulnerable to environmental stress including mechanical shocks and temperature variation, thus making powertrain reliability a key challenge for its designers. How the performance of one of these components might impact another needs to be considered by multiple parties. Thus, playing a vital role in deciding the reliability of the vehicle as a whole.

Generally, power components like motors, batteries and power electronics are more vulnerable to environmental stress including mechanical shocks and temperature variation, thus making powertrain reliability a key challenge for its designers. How the performance of one of these components might impact another needs to be considered by multiple parties. Thus, playing a vital role in deciding the reliability of the vehicle as a whole.