Introduction

Introduction

Traditional combustion engine vehicles emit engine sound, even at low travel speeds. Typically, pedestrians and other traffic participants recognize an approaching or departing vehicle through sight and auditory identification of tire sounds and other emitted noise when the vehicle is out of sight.

Electric vehicles (EVs) do not emit engine sound. Hybrid electric vehicles (HEVs) or plug-in hybrid electric vehicles (PHEVs) move almost silently when traveling at low speeds and before the conventional internal combustion engine (ICE) kicks in. These vehicles are difficult to hear when travelling at speeds less than 19 mph.

At greater speeds, tire sound becomes dominant.

Global governing bodies are exploring legislation that seeks to establish a minimum level of sound for PHEVs and HEVs when operating in electric mode so that visually impaired people, pedestrians, and cyclists can hear these vehicles approach and determine from which direction these vehicles are approaching. An example of this legislation can be found on the National Highway Traffic Safety Administration (NHTSA) website.

An electric vehicle warning sound system (EVWSS) produces a series of sounds designed to alert pedestrians to the presence of EVs, HEVs, and PHEVs. The driver can initiate warning sounds (similar to the sound from a car horn, but less urgent); however, the sounds must automatically be enabled at low speeds.These sounds vary from artificial tones to realistic sounds that mimic engine noise and tires moving over gravel.

Analog Devices offers two different solutions for advanced applications with an in-cabin engine sound for an EV as well as an external engine sound. Analog Devices developed a solution based on the ADSP-BF706. For entry-level systems, Analog Devices developed a solution based on the ADAU1450 SigmaDSP®. These solutions can synthesize sound and adjust frequency, sound volume, and other parameters depending on the traveling speed, and these solutions can send the audio to an audio power amplifier. Depending on the requirements of certain legislation, the warning sound can be simulated using combustion engine sounds or any other synthesized tones.

Blackfin-Based Solution

The ADSP-BF706 Blackfin+® processor provides a single-chip solution for audio processing and interfacing to the control area network (CAN) bus. Analog Devices developed a CAN software stack that runs on the ADSP-BF706, which enables users to build automotive grade demonstrations with minimal effort (a Vector® CAN stack can also be used). Additionally, Analog Devices provides full hardware and software reference design and SigmaStudio® compatibility for live tuning of parameters.

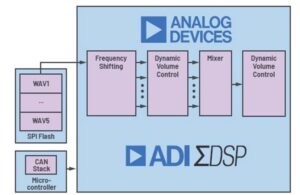

Figure 1 shows the different processing blocks inside the ADSP-BF706. External waveform audio files (WAVs) store signature engine sounds or audio tones. Up to 25 WAV files can be accessed simultaneously from the external serial peripheral interface (SPI). These files are frequency shifted and mixed internally in the digital signal processor (DSP) before adding the dynamic volume control.

The ADSP-BF706 utilizes a memory mapped SPI interface that provides faster, simplified access to the external memory, which eliminates the need for an external double data rate (DDR) memory for this application. Up to 25 WAV files can be accessed simultaneously from the SPI flash memory. The large number of accessible WAV files helps to create more realistic engine sounds.

The ADSP-BF706 can also implement up to 16× pitch shifting, a recommendation from the United States NHTSA, which increases the frequency of the output sound as the vehicle speed increases. The ADSP-BF706 can dynamically control the volume as the vehicle speed from the CAN bus increases.

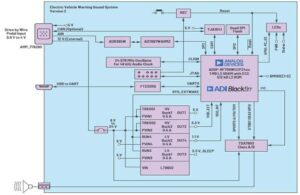

Figure 2 shows a detailed system block diagram. A Power by Linear™ LT8602 quad monolithic synchronous, step-down regulator provides all voltage rails required in the system, derived from the 12 V car battery supply. The 2 MHz switching frequency allows users to avoid critical, noise sensitive frequency bands—for example, the AM band. The 3 V to 42 V input v oltage range of the LT8602 makes the device ideal for automotive applications, which must regulate through cold crank and start stop scenarios with minimum input voltages as low as 3 V and load dump transients more than 40 V.

Figure 3 shows an alternative system block diagram with connectors, a reduced set of peripherals, and one automotive qualified connector carrying all relevant signals. This configuration allows the design of a smaller form factor board.

This system solution results in a reduced system bill of materials (BOM) cost because the ADSP-BF706 acts as a microcontroller and an audio processor.

For full details on the solution, see the EVWSS v1 Demo Manual and the EVWSS v2 Demo Manual, which are provided in the software download package. This software package (EVWSS-BF_SRC-Rel2.0.0) is available by request from the Software Request Form page on the Analog Devices website. For full details on the ADSP-BF706, see the ADSP-BF70x Blackfin+TM Processory Hardware Reference and the ADSP-BF7xx Blackfin+TM Processor Programming Reference.

EVWSS Software Architecture for the ADSP-BF706 Blackfin+ Processors

The EVWSS software architecture is based on the ADSP-BF706 hardware architecture. The processor dependence on the hardware architecture is due to the memory mapped SPI. The CAN interface reads directly from the flash memory using memory mapped SPI. This feature reduces the complexity of the EVWSS library and makes the memory access efficient for warning sound generation.

Software Components

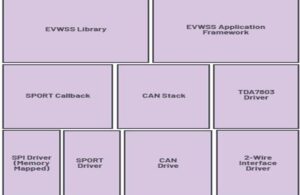

The EVWSS software architecture consists of the components shown in Figure 4.

This section details the software components. The SPORT callback feature maps to the audio data sample rate and runs in the SPORT transceiver interrupt service routine (ISR) context, reading flash files (SPI memory mapped), performing audio manipulation using the EVWSS library, and sending out modified audio on the SPORT transceiver interface. The EVWSS library holds the different functions to synthesize the warning sound. The EVWSS library also receives vehicle speed input from the CAN stack (or the universal asynchronous receiver and transmitter (UART) interface for debugging). The TDA7803 driver controls the external power amplifier to generate the warning sound. The EVWSS application framework configures the system peripherals, CAN stack, and the TDA7803 driver.

EVWSS Library Functions

The following sections describe the functions of the EVWSS library. For full details, see the Electronic Vehicle Warning Sound System Release Notes, which can be found in the software download package.

Pitch Control

Pitch shifting is the concept of shifting the spectrum of the audio signal based on a control input. In the EVWSS application, the base pitch of the WAV file is shifted depending on the vehicle speed input.

Frequency Modulation and Amplitude Modulation

The engine sound is dependent on the engine strokes, which include intake, compression, power (expansion), and exhaust. These strokes create frequency modulated tones instead of just pure tones. Vary the pitch shift parameter across the samples to achieve frequency modulation.

Two kinds of modulation (sawtooth and triangular) are included in this application. In sawtooth modulation, the frequency ramps from lowest to highest and then back to lowest with a jump. In triangular modulation, the frequency ramps from lowest to highest and then ramps back down to lowest.

Audio Mixing in Slew

For audio mixing, configure the various gains with respect to vehicle speed.

Playback of WAV Files

Although the required WAV files are present in flash, the user can play or stop some of the WAV files, depending on the dynamic conditions.

SigmaDSP-Based Solution

For entry-level applications, an ADAU1450 SigmaDSP processor can be used as an alternative to the ADSP-BF706 processor. For evaluation purposes, the EVALADAU1452 evaluation board can be used.

Figure 5 shows the different processing blocks inside the SigmaDSP processor.

The following software requirements are supported in the ADAU1450 using the SigmaStudio programming environment:

- Multiple tone generation

- Dynamic volume control with up to 64 ranges

- Sound mixing

- Limiter

- Pitch shifting that increases audio pitch as speed increases

- Simultaneous playback of up to 5 WAV files from the SPI flash memory

Analog Devices provides an engine sound simulator module in SigmaStudio to simplify engine sound tuning and reduce the number of external, simultaneous WAV files required. The engine sound simulator can internally generate up to 32 harmonics. The order and amplitude of these harmonics can be programmed through the graphical user interface (GUI).

The harmonic generator module is available as part of the ESS Toolbox. It can be downloaded directly from the SigmaStudio download page (Rev 4.4. upward). Note that SigmaStudio cannot support a CAN software stack, and an external microprocessor is required.

SigmaStudio

SigmaStudio is a graphical programming environment originally designed for the SigmaDSP portfolio of processors. This software has a built in library of algorithms developed specifically for automotive applications. The GUI simplifies the tuning process and provides controls and filter coefficients that can be varied on the fly without the requirement for writing code. SigmaStudio can be downloaded from the SigmaStudio page on the Analog Devices website.

Conclusion

Analog Devices offers comprehensive solutions for an entry-level system and for an advanced engine sound system that supports in-cabin engine sounds and external engine sounds. This article aims to ease the decision making process for the user, as well as reduce user time to market. Analog Devices offers a complete system solution, including the necessary software components for rapid prototyping and product development.

About the Authors

Andreas Pellkofer graduated from Technical University of Munich in electronic and information technology. He joined Analog Devices 2006 as an applications engineer working with the Blackfin processor family. Later he mainly dealt with automotive customers for DSPs. In 2013 he moved into a system engineer role in the Digital Video Products Group, focusing on video transport and camera systems for automotive. In 2018 he became part of the Emerging Systems and Technologies Group working on in-cabin vital sign monitoring and hands-on detection solutions. He can be reached at andreas.pellkofer@analog.com.

Andreas Pellkofer graduated from Technical University of Munich in electronic and information technology. He joined Analog Devices 2006 as an applications engineer working with the Blackfin processor family. Later he mainly dealt with automotive customers for DSPs. In 2013 he moved into a system engineer role in the Digital Video Products Group, focusing on video transport and camera systems for automotive. In 2018 he became part of the Emerging Systems and Technologies Group working on in-cabin vital sign monitoring and hands-on detection solutions. He can be reached at andreas.pellkofer@analog.com.

Jagannath Rotti graduated from PES Institute of Technology, Bangalore with a degree in electronics and communication. He has 13 years of automotive software experience. Prior to joining Analog Devices, he worked at Robert Bosch and Autoliv in the powertrain and safety domains, respectively. At ADI, he is a softw are lead in the Automotive SW Team, mainly working in cabin electronics in general and automotive audio buses. His areas of interest include automotive networks, network security and cryptography, audio algorithms, autonomous driving, sensor fusion, and Sanskrit literature. He can be reached at jagannath.rotti@analog.com.

Jagannath Rotti graduated from PES Institute of Technology, Bangalore with a degree in electronics and communication. He has 13 years of automotive software experience. Prior to joining Analog Devices, he worked at Robert Bosch and Autoliv in the powertrain and safety domains, respectively. At ADI, he is a softw are lead in the Automotive SW Team, mainly working in cabin electronics in general and automotive audio buses. His areas of interest include automotive networks, network security and cryptography, audio algorithms, autonomous driving, sensor fusion, and Sanskrit literature. He can be reached at jagannath.rotti@analog.com.

Danny Ko is an automotive system applications engineer for audio and emerging technologies based in Seoul, Korea. Danny joined ADI in 2004 as a DSP FAE supported Samsung, LG, and broad market for three years before changing his focus to automotive in 2007. In 2010, Danny transferred to the automotive segment as an automotive system application engineer and worked in the infotainment area, primarily in audio applications. Since 2018, his work has extended to emerging technology. He can be reached at danny.ko@analog.com.

Danny Ko is an automotive system applications engineer for audio and emerging technologies based in Seoul, Korea. Danny joined ADI in 2004 as a DSP FAE supported Samsung, LG, and broad market for three years before changing his focus to automotive in 2007. In 2010, Danny transferred to the automotive segment as an automotive system application engineer and worked in the infotainment area, primarily in audio applications. Since 2018, his work has extended to emerging technology. He can be reached at danny.ko@analog.com.