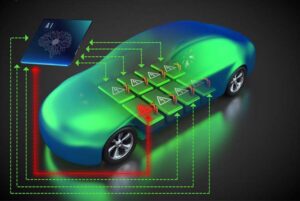

Eatron Technologies has enabled vehicle manufacturers to limit the risk of EV battery fires with the pioneering use of Artificial Intelligence (AI) in its advanced battery management software.

Vehicle fires are nothing new, regardless of the powertrain, but the recent emphasis has been on highlighting those involving electrified vehicles. As a result, vehicle manufacturers and the wider automotive industry now face the challenge of regaining the trust of consumers whose opinions of EVs may have been negatively impacted by recent publicity.

Vehicle fires are nothing new, regardless of the powertrain, but the recent emphasis has been on highlighting those involving electrified vehicles. As a result, vehicle manufacturers and the wider automotive industry now face the challenge of regaining the trust of consumers whose opinions of EVs may have been negatively impacted by recent publicity.

“The reality is that EV battery fires are incredibly rare, but even one is one too many,” explains Umut Genc, CEO at Eatron Technologies. “As an industry, we need to ensure the number of catastrophic battery failures reaches zero, and then stays there. Our intelligent, connected and safe automotive-grade battery management software has demonstrated that AI holds the key to achieving this.”

The causes of battery failure are complex, and often involve a combination of factors. One of the most common causes – lithium plating – occurs when metallic lithium deposits form around the anode. This is most likely during fast charging at low temperatures, and over time these deposits erode the performance of the battery. Left unchecked, this can lead to the growth of dendrites, needle-like structures that can pierce through the separator between the anode and the cathode, causing a short circuit within the cell. This in turn leads to a rapid self-discharge that can initiate thermal runaway, a self-sustaining chain reaction that is difficult to extinguish.

Detecting lithium plating without opening the battery cell and examining the electrodes – which is largely impossible once mounted in a vehicle – is a challenge that has been the subject of intense research. And while various techniques have been developed over the years, each has their own limitations, particularly when it comes to distinguishing lithium plating from other degradation mechanisms.

However, by using AI, Eatron Technologies has proven that it is possible to not only detect lithium plating far more effectively, but to accurately predict when it might occur.

“Using a technique called feature extraction, we transform the raw health data coming from the battery into a format that makes anomalies easier to identify. By combining this with our proprietary AI pipeline that accurately captures battery behaviour, our AI diagnostics can predict cell failures before they occur, with up to 90% accuracy and zero false positives,” continued Umut Genc.

Detecting a failure before it happens opens the door to dealing with it far more effectively and conveniently. That could mean altering the way the battery is managed to minimize any further damage in the short term, and ultimately to schedule a service visit for rectification at the driver’s convenience.