Electric vehicles (EVs) have revolutionized transportation, offering a sustainable alternative to traditional internal combustion engine vehicles. At the heart of every electric vehicle lies its traction battery pack, a crucial component that determines its performance, range, and reliability. With the global shift toward clean energy and the expansion of EV charging infrastructure, understanding the design and functionality of EV traction battery packs is essential for advancing the EV ecosystem.

What Are EV Traction Battery Packs?

Traction battery packs are the primary energy storage systems in electric vehicles. They provide the power required to propel the vehicle by supplying electricity to the electric motor. Unlike conventional lead-acid batteries used in starter motors, traction battery packs are high-capacity lithium-ion (Li-ion) batteries engineered for sustained energy output, high energy density, and longevity.

These battery packs enable EVs to achieve their hallmark features: zero tailpipe emissions, smooth acceleration, and reduced reliance on fossil fuels. As electric vehicles and EV charging networks continue to grow, advancements in traction battery design are critical for improving their efficiency and cost-effectiveness.

Components of an EV Traction Battery Pack

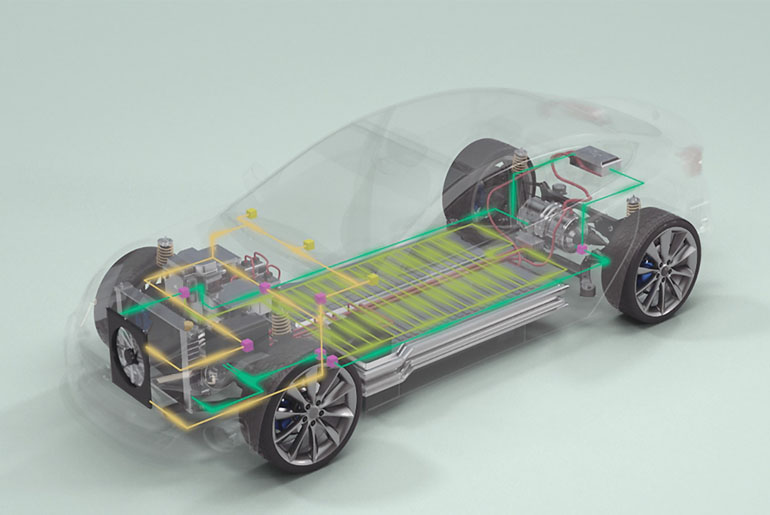

An EV traction battery pack is more than just a collection of cells. It is a sophisticated system comprising several essential components:

- Battery Cells

- Types of Cells: The battery pack consists of cylindrical, prismatic, or pouch cells, each with its design advantages.

- Chemistry: Lithium-ion chemistries like lithium iron phosphate (LFP) and nickel manganese cobalt (NMC) dominate due to their energy density and safety.

- Battery Modules and Packs

Cells are grouped into modules, which are then assembled into a battery pack. This modular design allows scalability for different EV models. - Battery Management System (BMS)

The BMS is the brain of the battery pack, responsible for monitoring cell voltages, managing temperature, and ensuring safe charging and discharging cycles. - Cooling System

To prevent overheating during operation or EV charging, battery packs are equipped with liquid cooling or air cooling systems. Thermal management is crucial for safety and performance. - Structural Components

The battery pack’s casing provides structural integrity and protection from external impacts. Lightweight materials like aluminum are often used to reduce vehicle weight.

Design Considerations for Traction Battery Packs

- Energy Density and Range

Energy density refers to the amount of energy stored per unit weight or volume. Higher energy density translates to longer ranges for electric vehicles. As EV charging stations become more widespread, increasing energy density remains a priority to reduce charging frequency. - Longevity and Cycle Life

Traction battery packs must withstand thousands of charge-discharge cycles. Enhanced cathode and anode materials, along with optimized BMS algorithms, ensure longevity. - Safety and Thermal Management

Safety is paramount in EV battery design. Features like thermal runaway protection, insulation, and advanced cooling systems minimize the risk of fires or failures. - Sustainability and Recycling

The environmental benefits of electric vehicles extend to battery recycling. Companies are focusing on recovering valuable materials like lithium, cobalt, and nickel to minimize waste.

Functionality of EV Traction Battery Packs

The functionality of traction battery packs is integral to an EV’s performance:

- Energy Storage and Supply

Battery packs store electrical energy, which is delivered to the motor controller to drive the vehicle. The efficiency of this energy transfer affects the vehicle’s range and performance. - Regenerative Braking

Many electric vehicles use regenerative braking to capture kinetic energy during deceleration, converting it back into electrical energy stored in the battery pack. - Integration with EV Charging Systems

EV charging is a critical aspect of battery pack functionality. Fast chargers can replenish batteries within minutes, while home charging systems allow for overnight charging. The battery’s ability to handle various EV charging speeds without degradation is a key design consideration. - Support for Vehicle-to-Grid (V2G) Technology

Advanced traction battery packs support V2G, allowing energy to flow back into the grid. This bidirectional capability enhances grid stability and enables EVs to act as mobile energy storage units.

The Role of EV Charging in Traction Battery Utilization

Efficient EV charging infrastructure is pivotal for the adoption of electric vehicles. Charging speed, convenience, and availability directly impact how users interact with their EVs. Key aspects include:

- Fast Charging: High-power chargers, such as 150 kW DC fast chargers, allow rapid energy replenishment for long-distance travel.

- Smart Charging: Integration with grid systems enables dynamic pricing and off-peak EV charging, optimizing energy use.

- Charging Compatibility: Standardized connectors and protocols ensure seamless charging experiences for various EV models.

The interplay between traction battery packs and EV charging solutions is shaping the future of mobility. As the number of EVs increases, battery packs must accommodate diverse charging scenarios while ensuring durability and efficiency.

Innovations in Traction Battery Packs

Advancements in traction battery technology are transforming the EV landscape:

- Solid-State Batteries

Promising higher energy density and improved safety, solid-state batteries are seen as the next breakthrough in EV technology. - Fast-Charging Materials

Innovations in electrode materials, such as silicon anodes, enable ultra-fast charging without compromising battery life. - Battery-as-a-Service (BaaS)

Subscription-based models allow users to swap depleted battery packs for fully charged ones, eliminating EV charging wait times. - Second-Life Batteries

After their automotive use, traction battery packs can be repurposed for stationary energy storage, supporting renewable energy integration.

Challenges and Future Directions

While traction battery packs have advanced significantly, challenges remain:

- Cost: Battery packs are the most expensive component in electric vehicles. Reducing production costs is vital for making EVs more affordable.

- Charging Infrastructure: Expanding EV charging networks, particularly in rural and underserved areas, is critical for widespread adoption.

- Sustainability: Addressing the environmental impact of mining raw materials and enhancing recycling practices will be key to ensuring the long-term viability of EVs.

The future of electric vehicles and EV charging is intertwined with the evolution of traction battery technology. Continued innovation in design, functionality, and integration will drive the global transition to sustainable transportation.

Conclusion

EV traction battery packs are the lifeblood of electric vehicles, enabling their environmental and economic benefits. Their design and functionality determine the range, efficiency, and overall user experience of EVs. As EV charging infrastructure grows and renewable energy integration deepens, the demand for advanced battery packs will only increase. By addressing challenges and embracing innovation, the industry is paving the way for a cleaner, more sustainable future powered by electric vehicles.